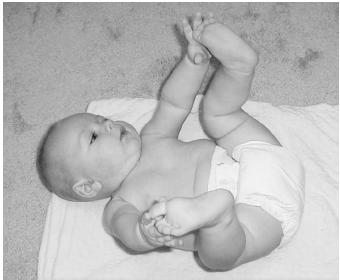

Disposable Diapers

During the past forty years, disposable diapers have become an important part of the economy. Since the average baby uses at least ten diapers per day for an average of two years, the convenience of the product has made it a very popular as well as controversial item. A recent survey by Texas A&M University reported that 81 percent of the participants exclusively used disposable diapers, 15 percent used cloth and disposables, while just 4 percent used only cloth diapers.

The disposable diaper of today is composed of an inner layer of polyester that allows liquids to pass through to a layer of absorbent material, and an outer waterproof plastic layer of polyethylene film. The design was developed by many researchers through trial and error.

History

It is not clear who should be credited as the inventor of the first disposable diaper. The need for disposable diapers arose during World War II because of a shortage of cotton, which was used in traditional diapers. One of the first effective disposable diapers was created by Marion Donovan during the postwar baby boom. She is also credited with inventing the first plastic covering for traditional cloth diapers. Using this plastic covering (made from a shower curtain) and layers of tissue paper as an absorbent inner material, Donovan devised the new diaper in 1950. These first diapers were rectangular in shape, resulting in a bulky fit. In the 1960s, pulp was substituted for the paper, improving the absorbency of the diaper. The top sheets of the diaper were modified by using rayon. These diapers still were quite thick and included no tape for closure. By the 1970s the demand for disposable diapers had increased, and more improvements were added. New tapes were added for ease of fastening, and the shape was changed from rectangular to "hourglass."

During the early 1980s, modifications were made to respond to the demand for a better-fitting and biodegradable product. Starch was added to the outer sheet to enhance its biodegradability. Elastic was added to the

waist and to the leg openings for a better fit. Unfortunately this added a nonbiodegradable component to the product. A new tape system was developed to allow for several tapings and retapings without tearing the diaper. In response to a greater demand for a more environmentally friendly product, a new filler, cellulose mixed with crystals of polyacrylate, was developed. The cellulose is processed from pine trees and milled into "fluff pulp." The pulp consists of long cellulose fibers that provide a strong capillary effect, which helps to draw in the liquid. The surface tension binds the water once it has been absorbed.

The polyacrylate (known as a "superabsorbent polymer" or SAP by the diaper industry) is distributed throughout the fluff pulp. Another name for these crystals is Waterlock™. It is also used for plants to help retain water in the soil. The polyacrylate under pressure can hold an amount of liquid that is as much as thirty times its weight. This correlates to the compression (pressure) that occurs when a baby would sit or lie on the diaper. The polyacrylate allowed the manufacturers to reduce both the weight and thickness of the diaper by 50 percent and increase its absorbency.

Polymer Chemistry

The polyacrylate used in the diaper is a large-molecular-weight compound called a polymer. It consists of small repeating units called monomers. The length of the chain as well as the properties of the polymer may be changed by varying the reaction conditions. If two monomers are used in the synthesis of the polymer, the resultant polymer is referred to as a copolymer. The polymer used in disposable diapers is prepared by using acrylic acid as the monomer:

To obtain the properties needed for the diaper, sodium acrylate is used in the polymerization. The reaction is said to use "partially neutralized acrylic acid." The exact proportion of the two monomers (acrylic acid and sodium acrylate) present influences the character of the polymer formed. The length of the chains (represented by n ) also is modified by reaction conditions and can change the characteristics of the polymer.

In addition to forming the chains of polyacrylate, the chains are cross-linked. This is a process in which two or more chains are held together by other compounds in a network. Typical cross-linkers for this polymer include di- and tri-acrylate esters. The swelling and elasticity of the polyacrylate polymer depends on the structure of this network and the number of cross-links. The swelling capacity of the polymer decreases with increased cross-link density. After formation, the polyacrylate is dried and formed into microparticles of irregular shape that can be stored for a long time.

When these particles come in contact with water, urine, or other aqueous solutions , they quickly swell and absorb the liquid. Typically it takes no more than five to ten seconds for this to occur. The ability to swell and absorb the water is dependent upon the ionization of the acid groups on the polymer chain. The amount of water uptake increases with the increase in concentration of ionized groups. This is due to an increase in repulsion between the ionized groups in the polymer. This allows for a greater amount of swelling of the polymer. The amount of liquid that is absorbed depends partly on the nature of the liquid. The polymer absorbs more pure water than it does solutions. This means that more urine, an aqueous solution, would be absorbed than pure water.

New Advances

Diapers continue to become thinner and more absorbent. During the 1990s a modification of the SAP was developed. It uses a surface cross-linker to reduce the "gel block" problem: If the absorbent is saturated with a liquid, it prevents the liquid from moving.

Independent inventors also are continuing to modify the diaper. Marlene Sandberg of Stockholm has constructed a diaper that is 70 percent biodegradable. She uses cornstarch in the preparation of the outer layer of the diaper. This allows her to reduce the amount of polyacrylate used by designing channels in the fill material that help disperse the urine. Other workers in the field dispute that the diaper is 70 percent biodegradable: They say the diapers will not degrade that much in a landfill—their ultimate destination.

Controversy

As with all products, there are advantages and disadvantages to disposable diapers. The new polyacrylate gel has been linked to some side effects, including allergic reactions such as skin irritations, and to toxic shock syndrome. In addition, the dyes in the diapers have been linked to damage of the central nervous system, and disposable diapers may contain low concentrations of dioxin, a by-product of the bleaching process used in the production of the paper pulp found in the absorbent layer. Dioxin has been linked to liver damage and immune system suppression.

Disposables are also considered to be an environmental threat. Only some of the materials used in the diapers are biodegradable (the wood pulp and SAP). The polyethylene and polyester sheets are not biodegradable; neither is the elastic used for better fit, nor the polypropylene used for the tape that is employed as a fastener. Disposable diapers account for up to 2 percent of the total volume of landfills in the United States. The lifetime of the diaper in the landfill depends on several environmental factors: soil condition, groundwater flow, and the presence of other materials in the soil.

SEE ALSO Materials Science ; Polymers, Synthetic .

Catherine H. Banks

Bibliography

Buchholz, Fredric L., and Peppas, Nicholas A., eds. (1994). Superabsorbent Polymers, Science and Technology. Washington, DC: American Chemical Society.

Lewis, R. J., Sr., ed. (1987). Hawley's Condensed Chemical Dictionary , 14th edition. New York: Wiley.

Internet Resources

Campbell, Todd. "Soaking It In: To Wash or Not to Wash? You Decide." ABC News.com 1999. Available from http://www.abcnews.go.com/sections/tech/Geek/geek991011.html .

"Diapers and Wipes: Frequently Asked Questions." Huggies. Kimberly-Clark Corp. Available from http://www.huggies.com/DiapersWipes/faqs/materials.stm .

Richer, Carlos. History of the Disposable Diaper. Available from http://www.gpoabs.com.mx/cricher/history.htm .

Schiff, Sherry. "The Diaper Dilemma." Waterloo Centre for Groundwater Research. Available from http://www.science.uwaterloo.ca/earth/waton/s891.html .

"What Is the Crystalline Substance Found in Disposable Diapers?" How Stuff Works. Available from http://www.howstuffworks.com/question207.html .

Comment about this article, ask questions, or add new information about this topic: