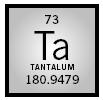

Tantalum

MELTING POINT:

2,996°C

BOILING POINT:

5425°C

DENSITY:

16.65 g/cm

3

MOST COMMON IONS:

Ta

3+

,

Ta

4+

Tantalum was discovered in 1802 by Swedish chemist Anders Gustav Ekeberg while analyzing Scandinavian minerals. He named the third-row early transition metal after the Greek god Tantalus, the son of Zeus, because the oxide was difficult to dissolve in strong acids.

Impure tantalum was isolated in 1825 by Swiss chemist Jean-Charles-Galissard de Marignac and, in purer form, by Heinrich Rose in 1844. It is found, in combination with its congener niobium, in tantalite/columbite (Fe, Mn)(Ta, Nb) 2 O 6 ore, with tantalite containing more tantalum than niobium. Its crustal abundance is 1.7 parts per million, with major deposits in Australia, Brazil, China, Africa, the former Soviet Union, and Canada. The ore is concentrated, refined to the oxide Ta 2 O 5 , converted to K 2 TaF 7 , and reduced to the metal .

Tantalum is a hard, ductile , dense, steel-blue (when unpolished) metal with the fourth highest melting point of all metals. It crystallizes in a body-centered cubic lattice with an atomic radius of 146 picometers. Tantalum has one stable isotope , 181 Ta; 180 Ta is a long-lived (half-life 1.2 × 10 15 years) isotope.

Tantalum is not attacked at 25°C (77°F) by concentrated bases or acids (other than hydrofluoric acid or fuming sulfuric acid) because of its adhering, corrosion-resistant oxide film. Important compounds, spanning the oxidation state range of −3 to +5, include tantalum oxide, Ta 2 O 5 ; the hard, refractory ceramic carbide TaC; the pentachloride TaCl 5 ; the refractory nitride TaN; reactive organometallic compounds with unusual molecular structures; and an interesting series of tantalum-tantalum bonded halide clusters (e.g., Ta 6 Cl 18 4− ) consisting of an octahedron of six tantalums with terminal and octahedral edge-bridging halides.

In 2000, 2,267 metric tons (5 million pounds) were produced for various applications, including: (1) electronic devices (79%), especially in capacitors for cell phones, portable computers, and video cameras where high volumetric efficiency and reliability are essential (the oxide coat on tantalum has a high dielectric constant and resistivity); (2) corrosion-resistant chemical process equipment; (3) filaments for evaporating metals; (4) high-temperature superalloys for gas turbines and jet engines; (5) high refractive-index optical lenses; (6) cutting tools; (7) screws and clips for surgical bone repair because of its biological inertness; and (8) radioluminescent x-ray image-intensifying phosphors for medical imaging.

Louis Messerle

Bibliography

Greenwood, N. N., and Earnshaw, A. (1997). Chemistry of the Elements, 2nd edition. Oxford, U.K.: Butterworth-Heinemann.

Internet Resources

Tantalum-Niobium International Study Center. Available from http://www.tanb.org .

Comment about this article, ask questions, or add new information about this topic: